Frame Connection Types

Weld-On Track Systems

A plain sided frame allows the customer to use their own connection methods and to incorporate the track system into an existing chassis design - our well-designed frames allow a secure interface. Please refer to our installation guide for mounting areas, or call to speak to our engineering team.

Bracketed Track Systems

Using machined plates, our mounting brackets can provide the customer with a simple ‘bolt-on’ solution that reduces assembly time and increases the serviceability of the machine. To discuss a possible bracket design please contact us for more information.

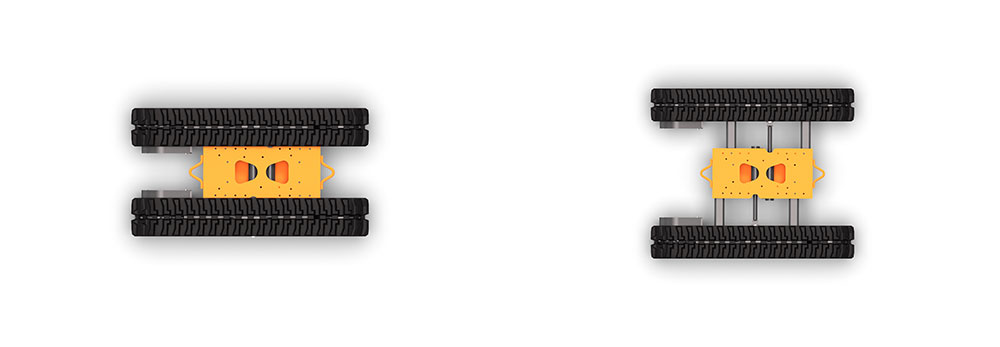

Extendable Track Systems

Strickland’s high performing, hydraulically powered variable width track system, provides the customer with complete flexibility. In its retracted state, the variable width track system enables the machine to navigate the smallest of spaces and, when extended, provide the machine with superb stability.

Cross Beam Track Systems

Our fabricated cross beam chassis design offers the customer the ultimate in assembly simplicity. This connection method allows the machine to simply be placed on top and fixed in place. Please contact us to discuss possible connection types.

Oscillating Track System

Strickland’s Oscillating Track Systems, typically found on drilling rigs, are precision manufactured to your specific requirements. The addition of a rubber belt reduces ground pressure without compromising on traction. Our unsurpassed engineering team will bring a concept to reality in an unrivaled timeframe.